Gearbox repair, maintenance and overhaul

STM team, with more than 40 years experience in gearboxes engineering, is proud to introduce you its new multi-branding service, a complete world of repair methods, aimed to lower our customers' costs, to maintain the highest performance and extend the life of their gearboxes and geared motors.

ALIGNMENT

VIBRATIONAL ANALYSIS

INFRARED THERMOGRAPHY

ANALYSIS OF LUBRICANTS

REVAMPING AND MAINTENANCE

NON-DESTRUCTIVE TESTS

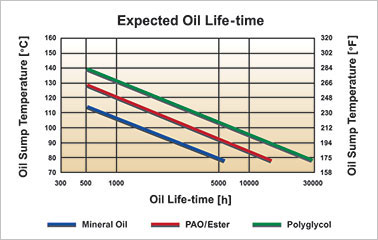

Compatible Alternative Oils for Planetary Gearboxes

Do you need to contact our multi-brand service, requesting advice from our experts?

Write to:

ALIGNMENT

It is important to perform a proper laser alignment for each new installation and whenever there is a mounted machine overhauled. In addition the alignment of machinery is one of the primary sources of savings in a company, cause it offers the following advantages:

- lower energy consumption by drive machines;

- longer duration of motion transmission;

- longer lasting bearings and supports;

- decreasing leaks in areas of transmission motion shafts;

- decreasing vibrations;

- reducing the number of hours for the maintenance of the machines, since they are less subject to wear.

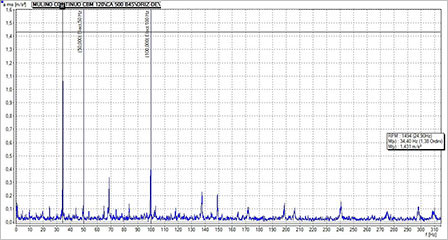

Vibrational analisys is a method based on the evaluation of parameters such as rotation, speed and acceleration of machinery or individual components. It allows you to diagnose the health of components, such as bearing and gears.

The analisys of machines' vibration can be carried out at the customers by portable instrumentation or using special remote control units.

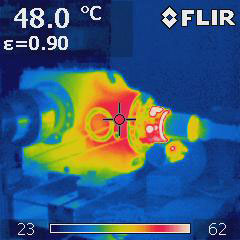

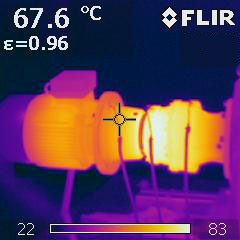

Infrared thermography (TT) is a non destructive control (NDT) technology, which is based on the measurement of infrared radiation emitted by a body (also defined by the irradiation time). Thanks to this acquisition it is possible to display bidimensional values of absolute ones and of temperature variations of the objects, regardless of their lighting in the visible field.

The analysis of lubricants is a very important procedure, it allows a clearer understanding about the state of the mechanical components and, therefore, the evaluation of their operation and condition. It enables us to:

- evaluate whether the lubricant is still suitable for use (from a chemical and physical point of view);

- check the percentage of metal particles in the lubricant film;

- control the viscosity, the acidity, the presence of moisture and non-metallic contaminants.

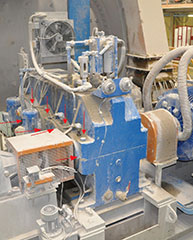

Gearboxes and geared motors revamping and maintenance offer a complete problem diagnosis, performing operations such as:

- gears and bearings substitution (also of big sizes);

- seal rings substitution;

- gears, wheels and gearbox parts designing and producing;

- damaged gears substitution and assembling of new ones;

- cast iron, aluminium and steel housings and flanges substitution;

- bearings supports substitution.

Non-destructive tests (NDT) are a series of controls and readings, which are very useful during the gearbox revamping and offer the following benefits:

- analysing the surface wear of the gears to know if they are still fit for use;

- verifying the integrity of welded (or not welded) housing and/or flanges, without destroying them.

Basically, the aim of non-destructive tests (NDT) in gear units is to identify the presence of superficial and structural defects. NDT commonly used are:

- MT (magnetoscopic) for wheels and pinions;

- UT (ultrasonic) or RT (radiographic) for housings and covers.

To download the table of Compatible Alternative Oils for filling STM Team Planetary Gearboxes, click here.

Preview: